| STANDARD ACCESSORIES |

OPTIONAL ACCESSORIES |

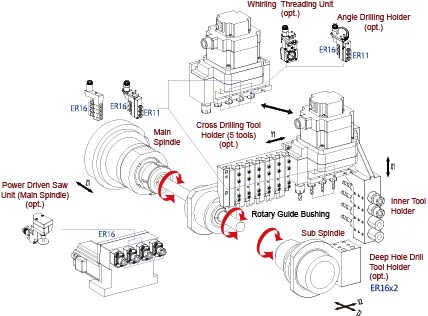

| External tool holder (6 tools) |

Hydraulic bar feeder |

| Main/sub-spindle Inne tool holder (4 tools) |

Chip conveyor & cart |

| Cross drilling tool holder (4 tools) |

Plug-in power head on the back axle |

| Dual C-axis |

Electrical cabinet air conditioning |

| Sub-spindle fixed tool holder (4 tools) |

Whirling Threading Unit |

| Lubrication device |

Millingtooth plate |

| Parts catcher & conveyor(Conveyor belt included) |

Cut-off inspection |

| Mechanical pads*6 pcs |

Long parts catcher(Sub-spindle) |

| Coolant device |

Oil mist collector |

| Working lamp |

Finished product conveyor belt (add-on) |

| Tools & tool box |

High pressure coolant system 70 bars |

| Operation manual |

Mitsubishi System |

| NC control operation manual |

Fanuc system SS-205E/265E/325E/385E |

| NC control maintenance manual |

Shake chip breaking |

| Tool overload shutdown system |

Deep hole drill holder type 32/38 is suitable |

| Transformer |

Side-turning end face eccentric drilling,tapping

tool holder (3 stations each of the main and

auxiliary spindles) |

| Non-guide bushing holder |

| Synchronous rotary guide sleeve |

|

| Pressure pusher*2 sets |

|

| Guide bushing |

|

| Spindle collet 2 pcs |

|

| Coolant inspection (Electronic type) |

|

| Sub-spindle fixed tool holder 4 pcs |

|

The counter-spindle machining toolholder

power motor |

|