Hybrid Sphere CNC Lathe

Hybrid Sphere CNC Lathe

SBL-100T

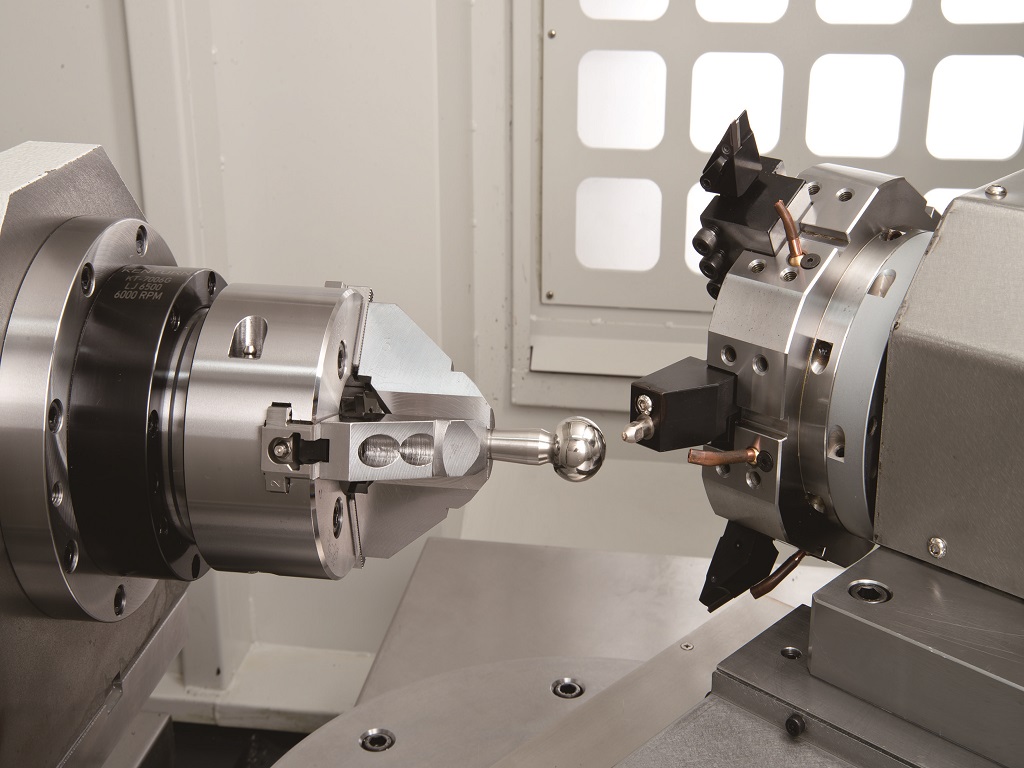

The SBL series is the ideal solution for making the components of steering system such as Ball pin and Tie Rod for inner ball joint and outer ball joint, medical implements such as femoral head for hip joint , Piston head for piston pumps and etc...

SBL-100T

The SBL series includes rough turning, fine turning, carbide roller burnishing, part pulling, and the cut-off process.

The burnishing process is an ideal way to enhance the surface hardness, extend the lifetime and enlarge the allowance of abrasion.

The burnishing process is an ideal way to enhance the surface hardness, extend the lifetime and enlarge the allowance of abrasion.

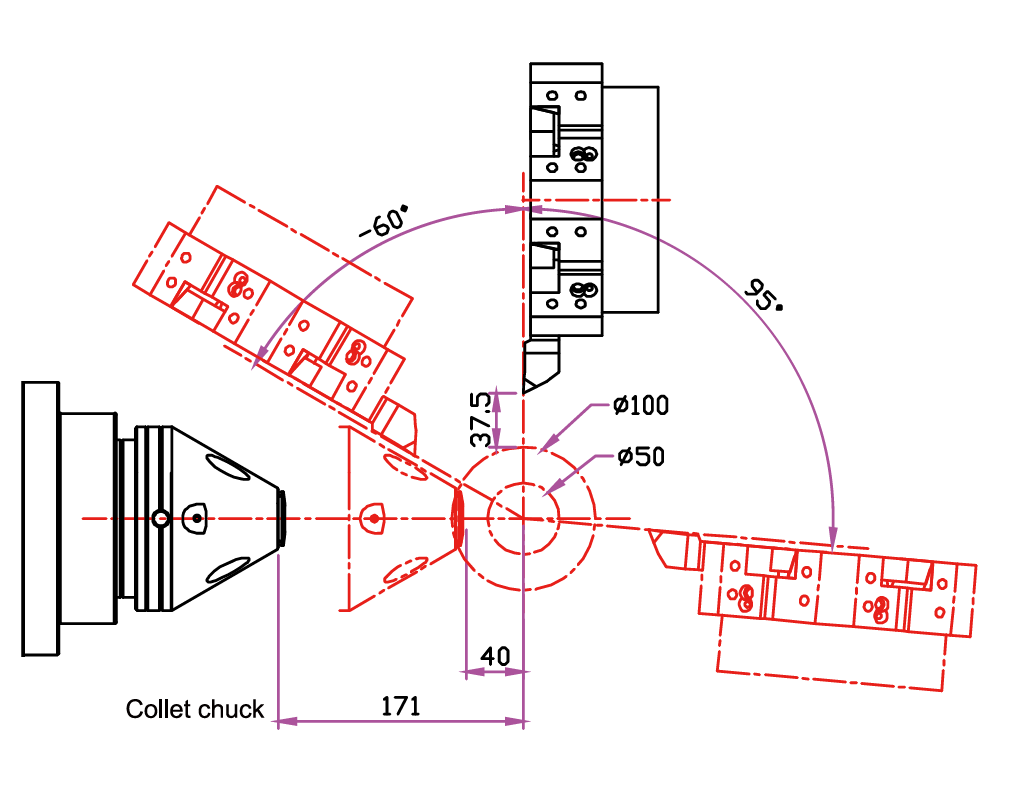

B axis - Ideal solution for great roundness

The trajectory of B axis can be close to a ball shape. The result of roundness can be achieved to ± 0.0055mm, which will be better than a conventional lathe, X and Z axis running simultaneously.

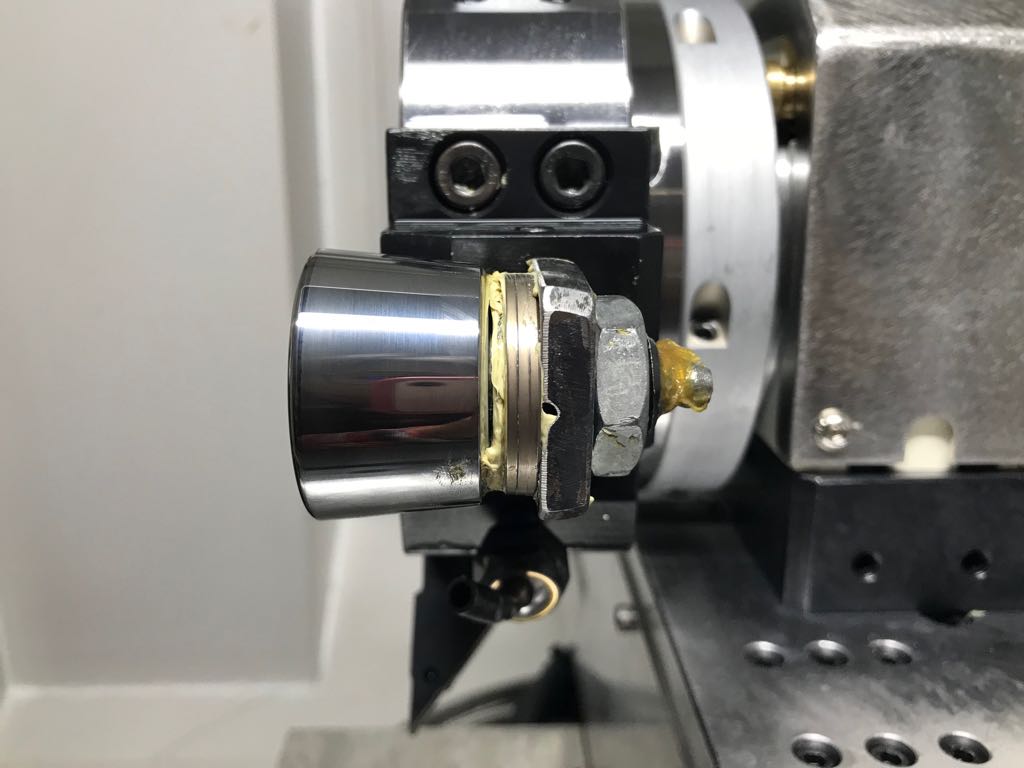

Burnishing Function Brightness surface

Burnishing is the process of extruding the surface by pressure, which will not consume the material as grinding does. Instead of modifying the dimension of work piece, burnishing will re-rank the metal molecules to remove the machining trace so that the surface can be strengthened and enhanced 10% to 30%. The roughness can achieve to Ra 0.1~0.2 μm

Workpiece showcase

The SBL series is the ideal solution for making the components of the steering system, such as Ball pin and Tie Rod for inner ball joint and outer ball joint, medical implements such as femoral head for hip joint , Piston head for piston pumps and etc...

The SBL series is designed for ball head machining, which is the best solution for high-quality sphere roundness and surface roughness.

The SBL series is designed for ball head machining, which is the best solution for high-quality sphere roundness and surface roughness.

| Model | Unit | SBL-100T | SBL-180T | SBL-250T |

|---|---|---|---|---|

| Swing over bed | mm | Ø350 | Ø500 | Ø520 |

| Max. turning diameter (ball head) | mm | Ø100 | Ø180 | Ø250 |

| Max. turning diameter (ball valve) | inch | Ø1/2"~2-1/2" | Ø2"~4.5" | Ø3"~6" |

| Spindle nose type | ASA | A2-4 | A2-5 | A2-6 |

| Spindle chuck type | - | 5C Collet Chuck16C Collet Chuck(Opt.)5" 3-Jaw Chuck (Opt.) | 16C Collet Chuck 6" 3 Jaw Chuck (Opt.) | 16C Collet Chuck 8" 3 Jaw Chuck (Opt.) |

| Spindle bore | mm | Ø45 | Ø56 | Ø62 |

| Spindle speed | rpm | 4000 (Std.) 6000 (Opt. ) | 3000 (Std.) 4500 (Opt. ) | 2000 (Std.) 4000 (Opt. ) |

| Spindle power | kw | 5.5kw (Std.) 7.5kw (Opt. ) | 7.5kw (Std.) 10kw (Opt. ) | 11kw (Std.) |

| X-axis motor power | kw | 1.2 | 1.2 | 1.8 |

| Z-axis motor power | kw | 1.8 | 2.5 | 2.5 |

| B-axis motor power | kw | 3 | 3 | 3 |

| X-axis travel | mm | 90 | 90 | 90 |

| Z-axis travel | mm | 90 | 90 | 90 |

| B-axis travel | degree | -60° / +95° | -60° / +95° | -60° / +95° |

| Z-axis rapid traverse rate | mm/min | 15000 | 15000 | 15000 |

| X-axis rapid traverse rate | mm/min | 15000 | 15000 | 15000 |

| B-axis rapid traverse rate | mm/min | 6000 | 6000 | 6000 |

| Number of tool station | T | 6 (Hydraulic turret) | 6 (Hydraulic turret) | 6 (Hydraulic turret) |

| Tool size | mm | 20x20 | 20x20 | 20x20 |

| Machine dimensions (LxWxH) | m | 2.5x1.9x1.8 | 2.8x2.2x1.9 | 3.1x2.3x1.9 |

| Voltage | - | 220V/60HZ/3P | 220V/60HZ/3P | 220V/60HZ/3P |

| Power requirement | kva | 20 | 25 | 28 |

| Weight | kg | 3000 | 3300 | 3800 |

Standard Accessories

- Collet chuck

- Hydraulic cylinder

- Hydraulic turret 6 position

- Power unit

- Pneumatic system unit

- Full guard

- Machine base

- Heat exchanger

- Automatic lubrication system

- Three color warning light

- Working lamp

- Coolant system

- Tool and tool box

- Wedge block

- Leveling bolts and blocks

- Operation manual

- Machine voltage: 220VAC / 60HZ / 3 phase

Optional Accessories

- Spindle motor upgrade

- Spindle speed upgrade

- X axis extend to 150 mm

- Z axis extend to 150 mm (for long part)

- Upgrade to hydraulic servo turret (8T)

- Upgrade to servo power turret (8T) with C axis

- C axis air breaking system

- 16C collet chuck and collet (work piece diameter less than Ø40 mm)

- Extention nose collet type chuck and collet (ball valve) with orientation pin

- 3 jaw chuck

- Chuck air blow

- Burnish diamond tool holder and tool

- Burnish diamond tool

- Chip conveyor and cart

- Transformer

- Voltage Stabilizer

- CE mark

This site uses cookies to improve your browsing experience. we'll assume you're OK to continue. If you want to read more about this, please check PRIVACY thank you.

Confirm