The Role of a Rotary Table in Machining

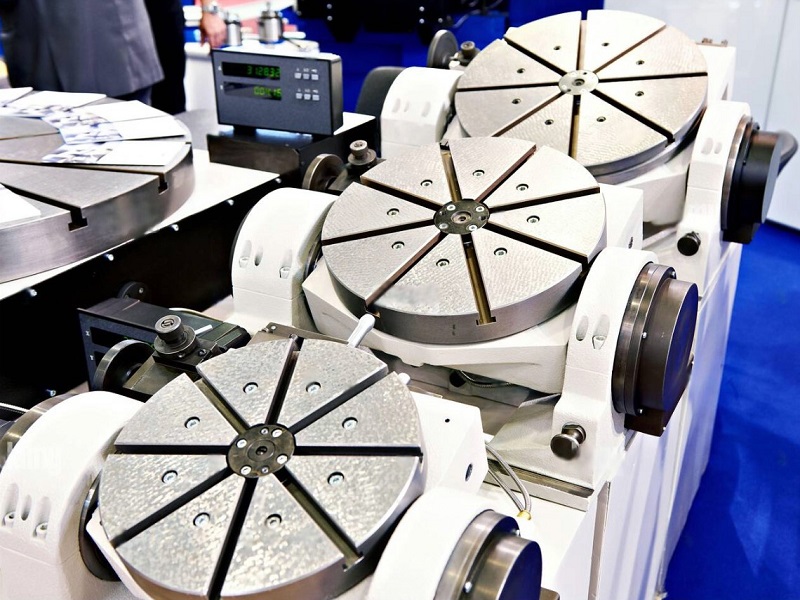

A rotary table enhances milling precision by rotating the workpiece, allowing for the machining of complex parts with ease. It facilitates multi-surface processing at fixed intervals, eliminating manual repositioning and ensuring accuracy.

![]() 1. Enables the Production of Large Components

1. Enables the Production of Large Components

Rotary tables support machining large components, like oversized wheels and gears, using indexing techniques for precise cutting on smaller machines. ![]()

![]() 2. Simplifies the Machining of Complex and Intricate Parts

2. Simplifies the Machining of Complex and Intricate Parts

They excel in creating intricate patterns and angular cuts, perfect for fabricating gear teeth at precise angles! ![]()

![]() 3. Produces Accurate Circular Features

3. Produces Accurate Circular Features

Rotary tables drill equidistant holes along a circular path, ensuring perfect arcs and circles—essential in industries requiring precision! ![]()

![]() Differences Between a Rotary Table and a Dividing Head

Differences Between a Rotary Table and a Dividing Head

While a rotary table provides general rotation, a dividing head specializes in precise angular rotations for tasks like gear cutting and creating helical paths. ![]()

![]() Investing in a Rotary Table is a Smart Choice

Investing in a Rotary Table is a Smart Choice

Investing in a high-quality rotary table significantly boosts milling operations' capabilities and accuracy, making it an invaluable asset. ![]()